The FRAMOS Static Dimensioner is an autonomous static precision solution with the capability to take accurate three-dimensional size and weight measurements for automated master data acquisition. It transfers data straight to warehousing, ERP and shipment systems for seamless post-processing in real time. FRAMOS will be showcasing its new logistics automation solution at FachPack 2016. The compact workstation comes complete with intuitive 3D software, is very easy to use and captures contact-free the weight and dimensions of items of any shape and with any type of surface in a single step. Dr. Simon Che’Rose, Head of Development at FRAMOS Imaging Systems, explains the benefits:

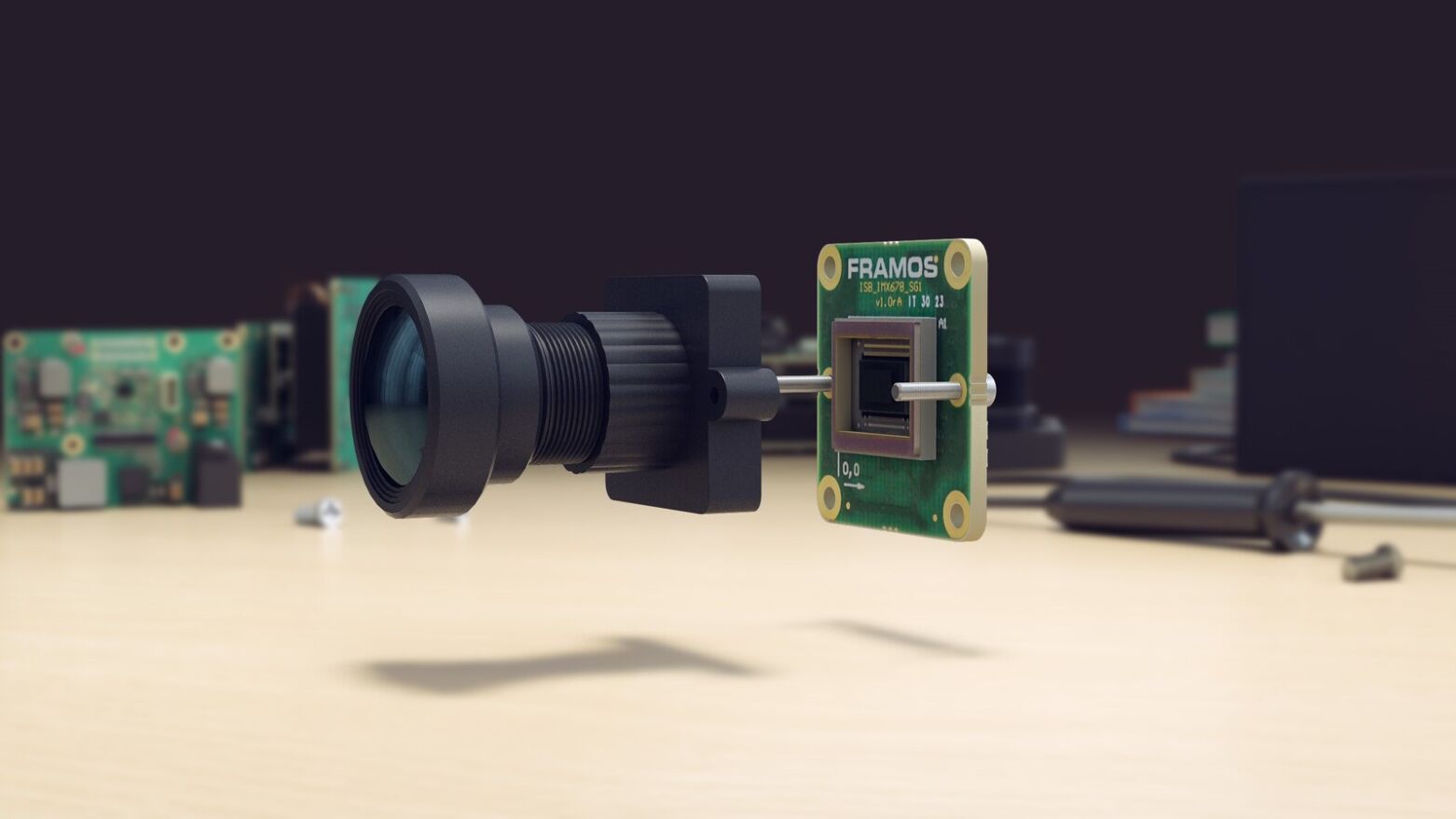

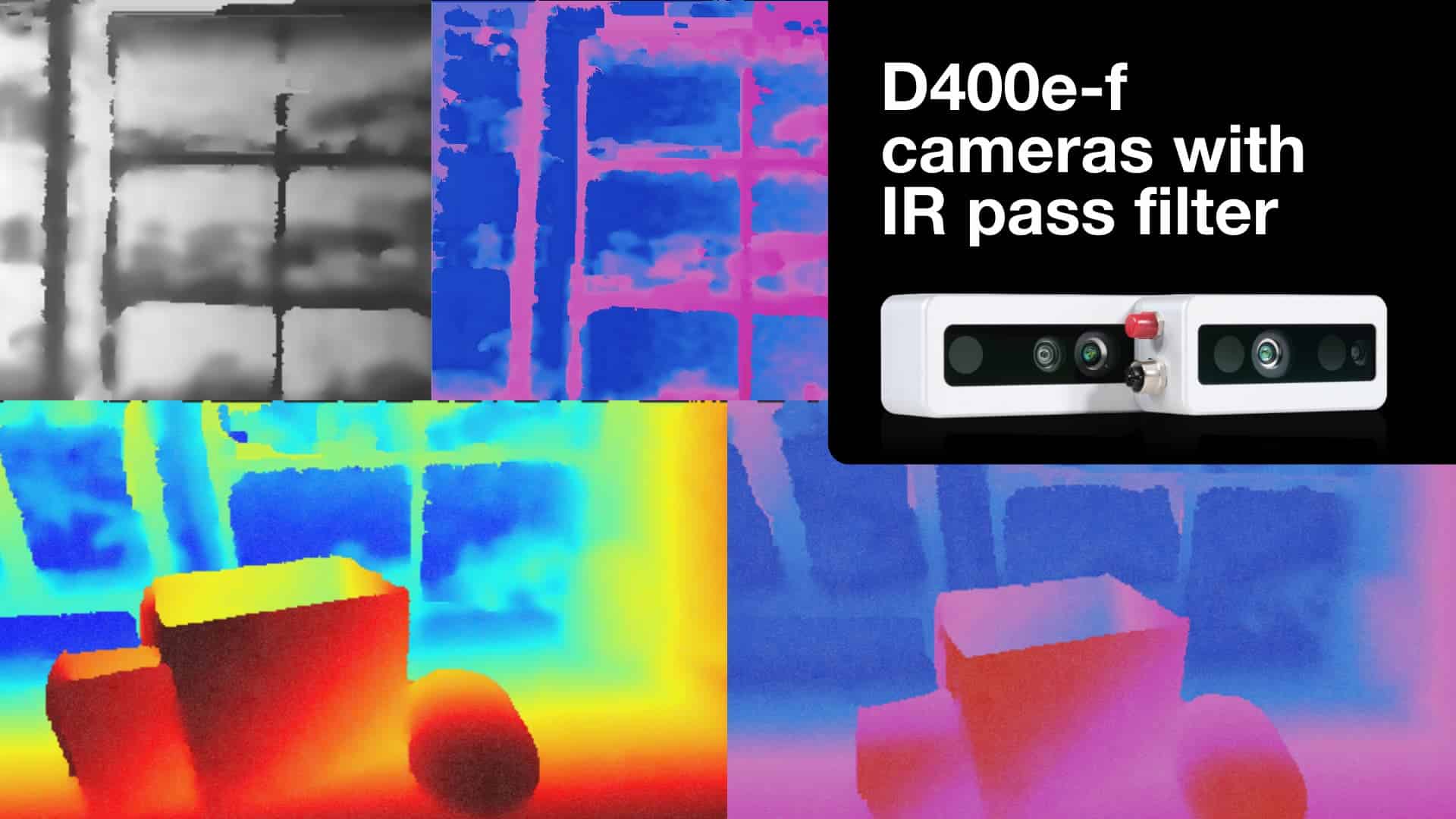

“Unlike laser-based processes, the Static Dimensioner also provides accurate results for partially transparent, black and shiny reflective items. It’s guaranteed to be reliable and easy to use thanks to a resilient sensor system, high measuring accuracy and high-quality mechanical components. We can customize the device based on customer requirements, with accessories like a barcode scanner for item identification, high-quality industrial cameras with up to 10 Megapixel resolution for image documentation and a portable battery for mobile use.”

An LED light grid with a 5 mm measuring resolution and, if required, a stand-alone power supply enables this maintenance-free measuring system developed by FRAMOS Imaging Systems to deliver reliable length, height and width measurements for goods of any shape. Its industrial weighing system is suitable for items up to 50 kg. It can be supplied pre-calibrated, if necessary, and the largest standard version will convey products up to 1,250 mm x 850 mm x 650 mm in size under the light grid. The Static Dimensioner supports seamless inbound/outbound goods logistics processes in almost any industry and, as a compact automated solution, it is especially useful for companies with a high portfolio turnover but no in-house conveyor unit. For instance, combined volume and weight measurements along with direct acquisition and transfer to linked warehouse management systems provide customers with the capability to optimise their warehouse in real time, complete with goods sorting and effective storage space calculation. Commercial audits can be run easily as part of delivery checks, based on data integrated into SAP. Data merging and identification processes support the downstream picking process. In freight management, load planning can be improved by utilising the collected master data. The Static Dimensioner also helps customers select the optimum loading equipment and exactly the right container size, reducing the empty spaces in their consignments. Optimising freight costs by using master data – including automated invoice creation and re-billing – can significantly cut costs as well as boosting revenues. Several FRAMOS customers are already using the system, which will be presented to an industry audience at FachPack 2016. The FRAMOS Imaging Systems experts will answer any questions about the product on booth 605 in hall 4A to and are open to discuss options for customized solutions.